16PPM

Key performance

Product Description

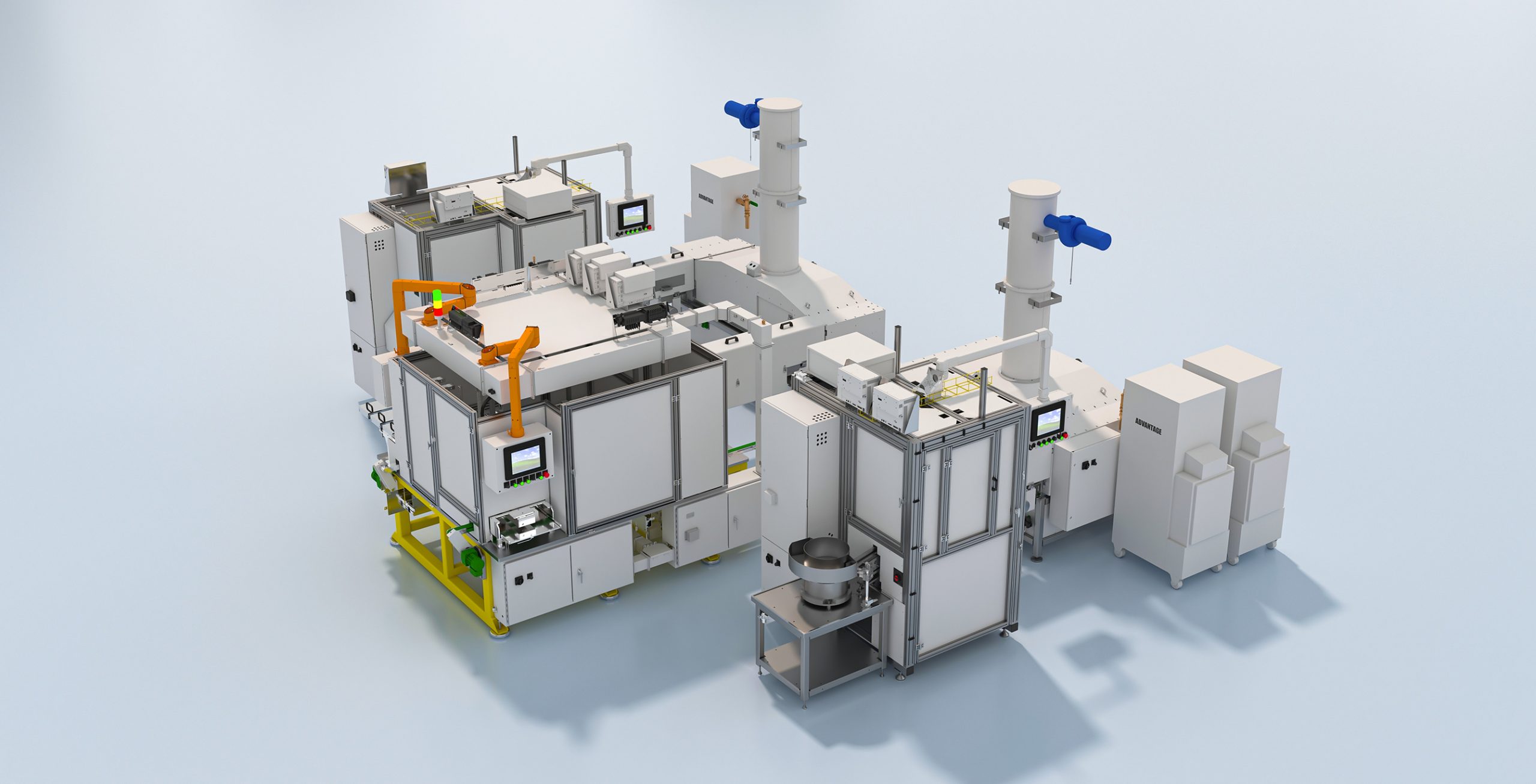

This equipment is mainly used for the assembly of igniters. The assembly process employs a dividing disc method for workstation assembly, with line transportation used for transferring products between equipment. Products are automatically loaded using a vibration disc and then enter the sizing station, where slurry is automatically added and relevant processes are completed. The products are then automatically transferred to the oven station for solidification. Subsequently, core pressing and welding are carried out sequentially. Finally, the product undergoes helium inspection testing to ensure quality.

Product Highlights

- The use of die cut coil material and the adoption of a peeling and pasting integrated adhesive machine reduce the space occupied by the production line.

- The adhesive machine adopts one backup and one use, achieving non-stop material replacement.

Basic Parameters

Beat

Liquid cooled energy storage plug-in box (4 modules)

1P52S≥16PPM

Key equipment CMK

≥ 1.67

Equipment failure rate

Module automatic line:≤8%

One time offline qualification rate

Module≥98%,PACK≥99.5%

(Defects caused solely by equipment)

Get a solution now

We provide tailored project plans based on a detailed assessment of your business needs, current project progress, and an in-depth analysis of industry competitors. Reach out today for a custom solution!

"*" indicates required fields