12.9s

Production Cycle Time

Product Description

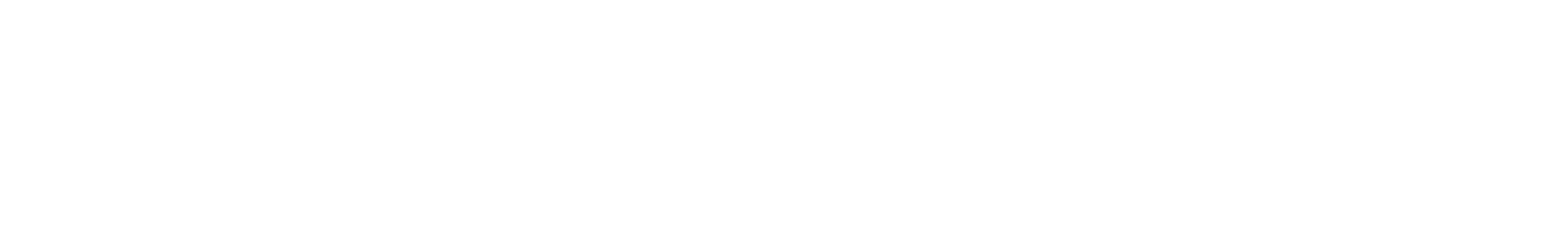

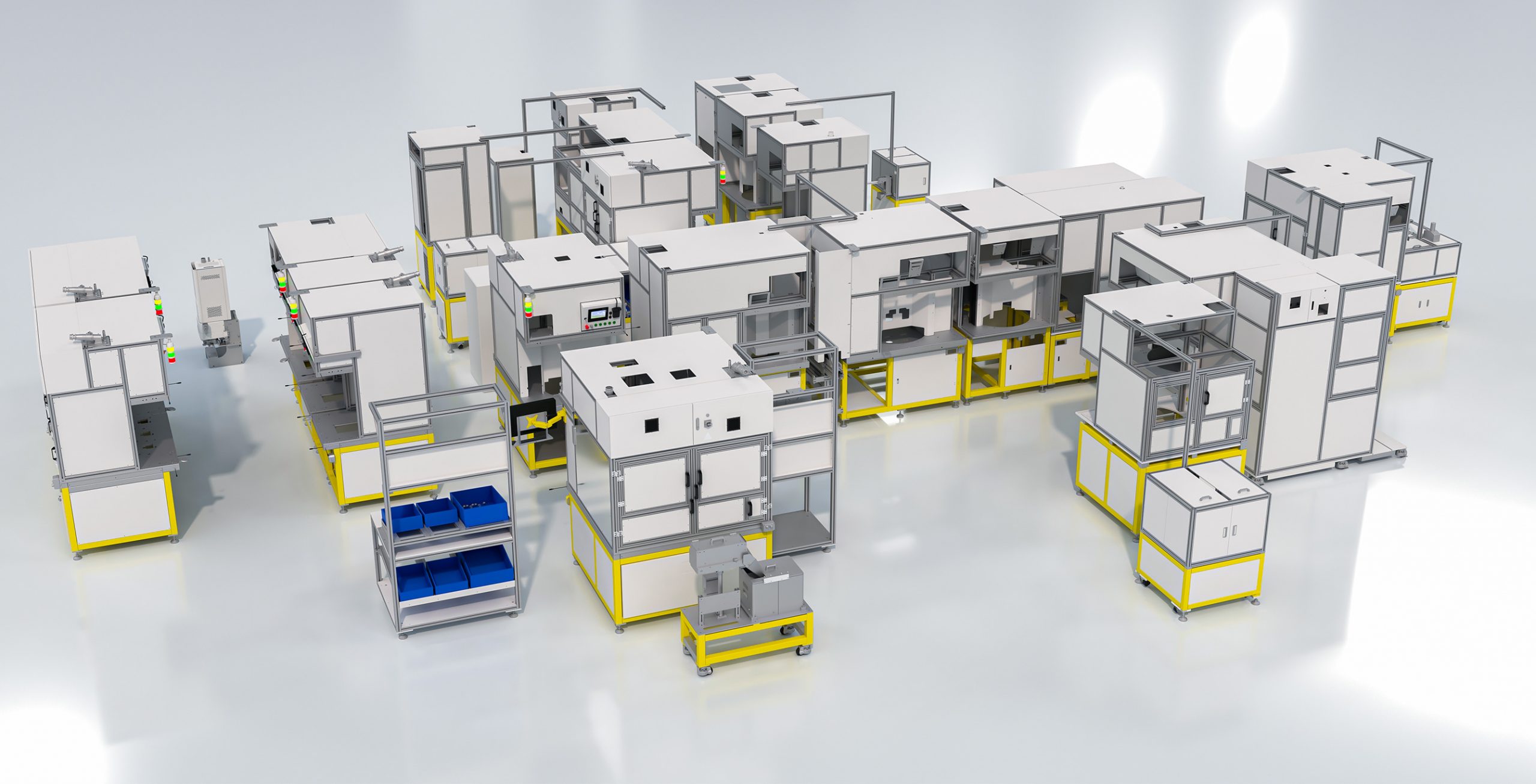

The coolant flow control valve production line adopts a semi-automatic method to achieve automatic feeding, magnetization, PCBA installation, oiling, gear installation, backlash detection, sealing ring installation, ultrasonic welding, airtightness testing, EOL detection, laser engraving, and screwing for the water valve components. And a traceability system has been set up for the product, providing reliable and stable support for the excellent product quality of customers.

Product Highlights

- The equipment meets safety regulations and ergonomics, featuring a stable product fixture system, a reliable tightening system, and a dependable product rotation system.

- The accuracy of assembled components meets the precision requirements outlined in the drawings.

- The equipment has a neat and aesthetically pleasing appearance.

- The equipment has been optimized in design, with a reasonable arrangement of workstations, product process flow, and transmission methods, significantly improving efficiency.

- The design of each process mechanism is reliable, ensuring stable operation.

- The layout of manual operation workstations and operation ports is reasonable, making it convenient for personnel to operate, reducing labor intensity, and ensuring the continuity of equipment operation.

Parameters

Production Capacity

1.6 million pieces/year

Equipment Utilization Rate

85%

Get a solution now

We provide tailored project plans based on a detailed assessment of your business needs, current project progress, and an in-depth analysis of industry competitors. Reach out today for a custom solution!

"*" indicates required fields